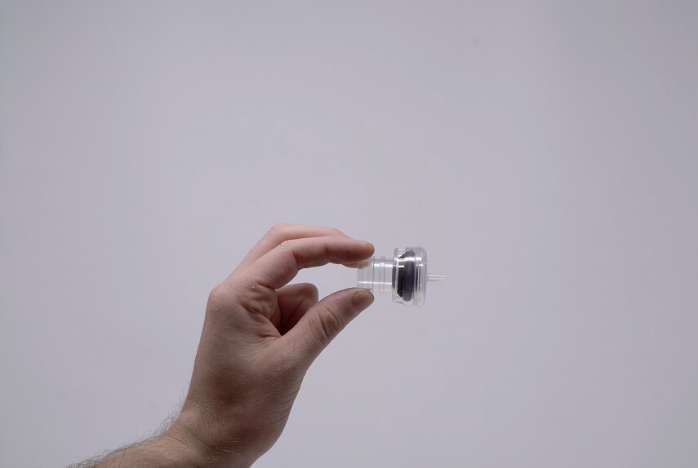

Recently, our CEO Walter Voit was interviewed by Fabbaloo on our production of PEEP (positive end-expiratory pressure) valves and nasopharyngeal swabs during the outbreak of COVID-19. With the predicted shortage of ventilators for patients on breathing support and nasal swabs for coronavirus testing, we knew we had to act. Adaptive3D was able to produce life-saving ventilator parts and start manufacturing 3D-printed valves in just three days.

“Ventilators too have required more parts to be developed and made to help those patients suffering some of the worst complications of this new virus. 3D printed diaphragms offer faster development and turnaround time to keep these life-saving devices operable. There’s a good amount of finesse that’s gone into these pandemic-response designs.

But it’s not just about the design: those qualities require a high-quality material to make such devices. And that’s where companies like Adaptive3D come into the conversation.”

Sarah Goehrke, Author at Fabbaloo

Our proprietary technology has proven the additive manufacturing industry is capable of adapting its functions to the world’s needs. With our production of PEEP valves as well as nasopharyngeal swabs, we are excited to see the direction that 3D printing is heading in. Thank you to Fabbaloo for showing the impact of Adaptive3D during COVID-19. To read the full article, click here.